Solar Field Construction Disputes Are Heating Up—How Utilities and Contractors Can Manage Cost Overruns and Schedule Delays

As a surge in utility-scale solar projects converges with shifting trade policies and regulations, new threats to project budgets and completion dates arise when demand for solar energy is at an all-time high.

An unprecedented demand for solar energy infrastructure in the United States is on a collision course with trade and policy shifts, setting the stage for a surge in project risk that stakeholders must consider to mitigate exposure to cost overruns, delays, claims, and disputes.

The continuing artificial intelligence (AI) boom and cryptocurrency computing needs have led to record-breaking demand for electricity consumption in 2025 and 2026, much of which will come from energy generated by solar facilities. According to the US Energy Information Administration (EIA), the US power grid is expected to add 63.0 gigawatts (GW) of new utility-scale electric-generating capacity in 2025. This is an increase of 30 percent and 94 percent, respectively, in new capacity compared to 48.6 GW in 2024 and 32.4 GW in 2023.

The industry expects an average of 43 GW will be added to the power grid in the United States each year through 2030, suggesting that the demand for solar energy is here to stay for the foreseeable future.

The EIA forecast that over 50 percent of new electricity generation capacity this year in the United States will come from solar fields. This projection includes a 30 percent increase in battery storage capacity that can temporarily store the energy generated from solar facilities.

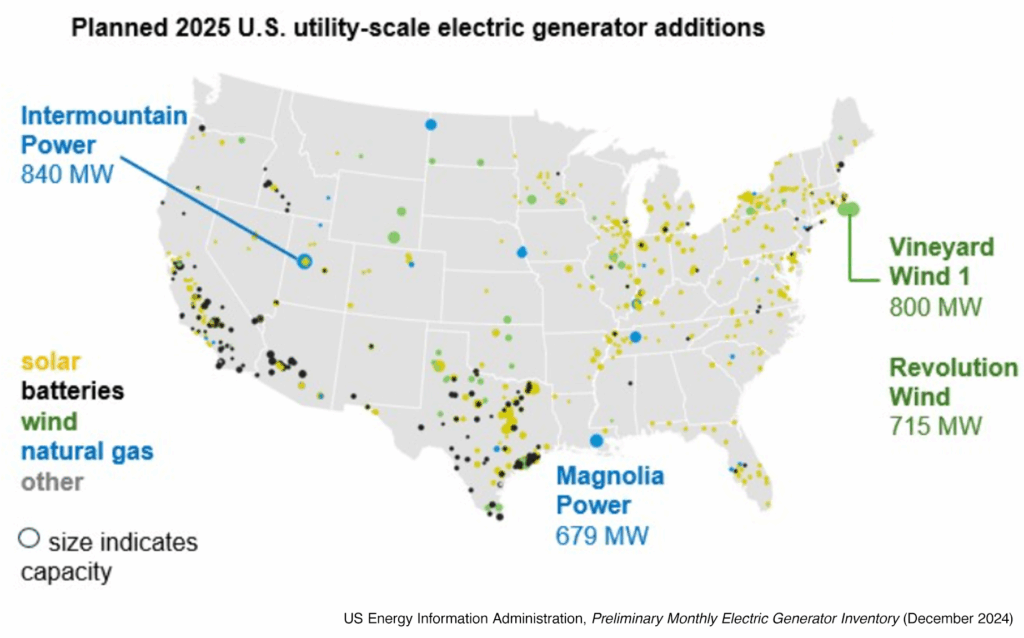

Figure 1: Locations of New Electric Generating Additions in United States

At the same time, changing trade policies and tariffs threaten to disrupt supply chains and cause complications that may lead to time and cost impacts. Changes to anti-dumping and countervailing duties on critical materials from abroad may alter supply chains to ongoing projects. In addition, changing tax credits and tariffs may significantly affect the expected cost of larger solar projects. These factors may result in cost increases, time impacts, and red tape to solar projects, introducing an elevated likelihood of claims and litigation if left unaddressed.

Demand for solar power is expected to remain consistent in the coming years; however, it appears that energy providers and their construction contractors may need to find ways to work through some challenges to keep up with demand. Below we discuss factors that parties to the construction of a solar field may consider when contemplating strategies to manage and mitigate risks.

Known Drivers of Cost Overruns and Schedule Delays on Solar Projects

- Supply chain interruptions or complications: These could mount in light of new tariffs and regulations, inhibiting developers’ abilities to source materials abroad. This could be significant, as nearly all US-made solar panelsuse at least some components from overseas.

- Permitting problems: Solar developers may face opposition to or rejection of permits due to zoning ordinances, environmental concerns, historical preservation rules, or community pushback.

- Weather: Heavy rains, excessive snow, hurricanes, wildfires, and tornadoes all can cause intermittent and continued delays to the solar field construction process.

- Interconnection issues: A lack of standardization in interconnection procedures among new facilities and existing grids can make planning and coordination increasingly difficult.

- Sufficient workforce: Shortages of qualified working personnel can halt progress and result in delays, rework, cost overruns, and even litigation.

- Design modifications: Solar developers often must revise engineering designs, whether relating to compliance with new environmental regulations, differing site conditions, shifting weather conditions, or supply chain bottlenecks. Delays may follow if not managed closely.

- Unexpected environmental regulations: A South Carolina judge recently issued a stay in a lawsuit in which plaintiffs argue that a manufacturing plant poses environmental and safety risks to nearby properties and schools.

These factors can lead to delays and significant cost impacts that, if not addressed ahead of time or timely, can quickly result in claims and litigation related to pricing changes, breaches of contract, and noncompliance with environmental and zoning regulations.

Best Practices for Utilities and Construction Contractors to Mitigate Risk

Energy utilities and construction contractors alike would do well to consider the following best practices:

- Put the right team in place, including engineering designers and contractors that understand solar projects, reliable subcontractors that have access to quality labor, and material and equipment providers that have ample experience with utility-scale solar projects.

- Perform sufficient planning with stakeholders to account for unique site and project conditions that address site layout and logistics, supply chains, work sequencing, and safety protocols.

- Procure quality equipment and materials that may not be as susceptible to weather conditions and likely will perform better and for longer periods.

- Sufficiently prepare the site ahead of construction activities to ensure functioning and compliant stormwater management systems exist to prevent flooding and soggy ground conditions.

- Optimize project scheduling by developing a reasonable schedule of work, including subcontractors and material suppliers in the schedule development and update process; and by identifying alternative work sequences should unexpected conditions or events occur.

- Maintain clear and open lines of communication among all parties, including regular communication between the general contractor and the utility regarding unexpected issues so that solutions are developed timely as a team.

- Be prepared to implement contingency plans if unexpected events occur. This may include procuring alternative labor sources if existing subcontractors encounter labor shortages; or having alternative equipment and material suppliers available in case of price fluctuations or supply chain complications.

- Maintain a complete understanding of environmental regulations and requirements regarding protected waterways and species, permitting, stormwater management and erosion and sediment controls, and disposal of hazardous materials.

- Begin the grid interconnection coordination process early. Some utilities have undeveloped or inconsistent protocols for the connection of new solar facilities to the existing grid. Contractors and utilities alike would do well to begin the interconnection conversation early.

- Maintain sufficient quality control protocols to timely identify variances from required work standards and specifications. Addressing quality issues sooner may prevent cost overruns, delays, claims, and costly litigation.

- Mitigate weather delays through sufficient research of historical weather patterns and accounting for similar conditions in initial project timelines, maintaining flexibility in working days and shifts to mitigate weather impacts, and maintaining clear records of actual adverse weather conditions.

- Implement “lessons learned” after the completion of each project to capture project successes and challenges that can be referenced ahead of the next project. This allows teams to quickly leverage previous experience instead of reinventing the proverbial wheel for each project.

As demand for solar energy continues, utilities and contractors will have plenty of partnering opportunities in the coming years. But numerous complications now pose a threat to bringing these projects in on time and within budget. With the right planning and risk mitigation techniques, all parties can take steps to manage the time and cost impact of these risks.

Based out of Atlanta, Georgia, Caleb Sturm and Hannah Jackson are part of BRG’s Global Construction advisory practice.